|

DESIGN ADVANTAGES

- Solid

thermoplastic body and bonnet for best overall corrosion resistance.

- Large diameter

molded in stainless steel diaphragm stud for long life service.

- Fully lubricated

brass or cast iron stem and sleeve. Sizes 3" and larger have bonnet

grease fitting for ease of in service lubrication.

- Extra heavy EPDM

diaphragm or optional PTFE diaphragm fully backed by EPDM, for long

service life under the most severe conditions.

- Unique

concave/convex PTFE/ EPDM diaphragm design insures PTFE barrier returns

to full open position.

- Standard,

adjustable full close position over travel stop to eliminate premature

diaphragm failure due to overtightening.

- Full stroke,

fully protected open/close position indication.

- Stainless steel

or plastic encapsulated external hardware.

- Longer service

life and higher Cv valves than rubber lined valves.

- High pressure,

temperature and vacuum service rated, suitable for most applications.

- Can be used in

lined, metal FRP or thermoplastic piping systems.

- Flanged

application valves designed to fit between ANSI B16.5 Class 150 flanges.

|

*

|

Valves 1/2" - 2 1/2" can be used in vacuum service.

Valves 3" and larger must be ordered special from the factory for use

in vacuum service. Consult factory for more information regarding this

option.

|

|

Materials of Construction

|

|

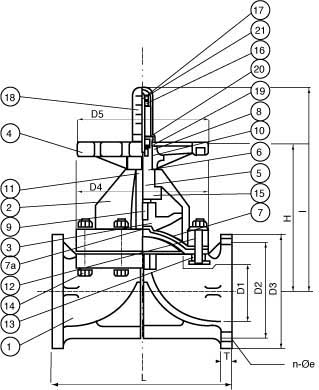

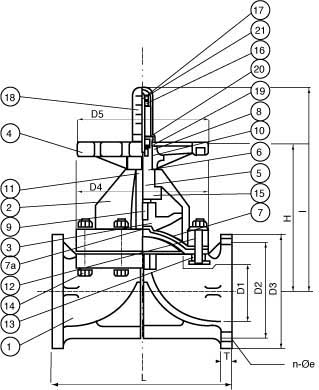

Item

|

Parts

|

Pcs

|

Materials

|

|

1

|

Body

|

1

|

PVC, PP, PVDF, CPVC

|

|

2

|

Bonnet

|

1

|

PVC, PP, PVDF, CPVC

|

|

3

|

Compressor

|

1

|

1/2"-1" PPG+Nylon

1/2"-10" Cast Iron

|

|

4

|

Hand Wheel

|

1

|

PP

|

|

5

|

Sleeve

|

1

|

1/2"-2" Brass

21/2"-10" Cast Iron

|

|

6

|

Stem

|

1

|

1/2"-2" Brass

21/2"-10" SS 41

|

|

7

|

Diaphragm

|

1

|

EPDM, HYPALON TEFLON?/small>

|

|

8

|

Cap

|

1

|

1/2"-2" Brass

21/2"-10" PVC,PP

|

|

9

|

Compressor Pin

|

1

|

SUS-304

|

|

10

|

Name Plate

|

1

|

PVC

|

|

11

|

Grease Nipple

|

1

|

BRASS

|

|

12

|

Stud Bolt & Nut

|

|

SS41, SUS304

|

|

13

|

Inserted Nut

|

|

BRASS

|

|

14

|

Bolt Nut & Washer

|

|

SS41, SUS304

|

|

15

|

Thrust Bearing

|

1

|

Standardized 3" - 10" Used Only

|

|

16

|

Stopper

|

1

|

SS-41, BRASS, SUS304

|

|

17

|

Set Nut

|

1

|

SS-41, BRASS, SUS304

|

|

18

|

Gauge Cover

|

1

|

POLYCARBONATE

|

|

19

|

Sheet Gasket

|

1

|

EPDM

|

|

20

|

Sheet Ring

|

1

|

SS-41, BRASS,SUS304

|

|

21

|

Spring Washer

|

1

|

SS-41, SUS304

|

VITON?is a trademark of Dupont Dow

Elastomers

TEFLON?is a trademark of E.l. DuPont

FLANGED BODY TYPE 1/2" - 10" DIAPHRAGM VALVES

DESIGN SPECIFICATION

Thermoplastic Diaphragm Valves 1/2" - 10" Flg.; shall be

molded of solid thermoplastic materials for body and bonnet. Body is of the

weir configuration exhibiting large flow area and good flow control

capability. Body is designed to fit between ANSI B16.5 class 150 flanges.

Stem and sleeve shall be brass or cast iron, fully lubricated . Sizes 3"

and larger employs a bonnet grease fitting for ease of lubrication. All

valves shall have an adjustable overtravel stop in the close position to

prevent overtravel and premature diaphragm failure. Full stroke position

indication is enclosed in a clear protective cover. All external fasteners

shall be either encapsulated in plastic or of stainless steel materials.

Materials of construction shall be: (select as required for service)

BODY

PVC,CPVC,ASTM D-1784,PP,ASTM D-4101,PVDF, ASTM

D-3222

BONNET

PVC,CPVC,ASTM D-1784,PP,ASTM D-4101,PVDF, ASTM

D-3222

STEM/SLEEVE

Brass, 1/2" - 2",

C.I., 2 1/2" - 10"

DIAPHRAGM

EPDM, Ethylene Propylene Diene Monomer

Fluorocarbon, Viton (E.I. Dupont) for vacuum service only

Fluorel (3M Corp.)

PTFE/EPDM, Teflon (E.I. Dupont)

DIAPHRAGM INSERT STUD

Stainless Steel, Large Diameter

POSITIVE INDICATOR COVER

PC, Polycarbonate, ASTM - D-2848

HANDWHEEL

ABS, ASTM D-1788

Not recommended for compressed air or gas service.

|